rockwell hardness tester brinell tensile strength|rockwell vs brinell hardness test : bulk The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. web22 de abr. de 2017 · Cinesystem Cinemas. "O melhor cinema da Ilha do Governador (vale dizer que é o único)." (11 dicas) "Filas imensas também para comprar pipoca e refrigerante." (4 dicas) "Cinema ótimo com várias salas e diversão garantida." (11 dicas) Faça login para deixar uma dica aqui.

{plog:ftitle_list}

27/02/2024 - 23:00. Jacobina. Se inscreva no Censo Cultural de Jacobina. A Prefeitura de Jacobina (PMJ), por meio da Secretaria Municipal da Educação e Cultura (SEMEC) e Diretoria da. 27/02/2024 - 22:55. .

rockwell vs brinell hardness test

The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. For plain carbon steels, the approximate relationship between the hardness and .Conversion of hardness-to-hardness or hardness-to-tensile-strength values for unalloyed and low alloy steels and cast steel per. ISO 18265 - 2013. Hardness conversions are no substitute .

The following two conversion tables come from standard ASTM A 370. Table A is the comparison between Rockwell C Hardness, Brinell Hardness, Vickers Hardness and tensile strength (Rm). Table B is the comparison between HRB, BH, HV and Rm, refer to iron-foundry.com. Table A - HRC to HB, HV, Rm

Tensile strength from Brinell hardness can be roughly estimated by multiplying 3.45 and Brinell hardness is calculated using Tensile Strength = (3.45/9.8067)*Brinell Hardness.To calculate Tensile strength from Brinell hardness, you need Brinell Hardness (HB).With our tool, you need to enter the respective value for Brinell Hardness and hit the calculate button.

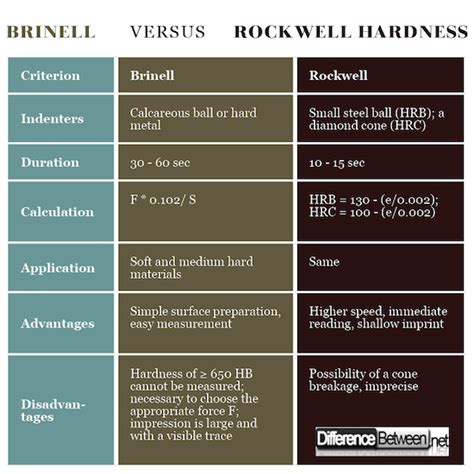

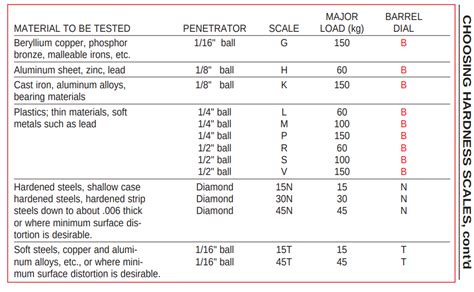

A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a .A convenient conversion fact is that of Brinell hardness to ultimate tensile strength. For quenched and tempered steel, the tensile strength (psi) is about 500 times the Brinell hardness number (provided the strength is not over 200,000 psi). Related: Brinell and Rockwell Hardness Conversion ChartHigh Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .

Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 290 MPa. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration .

Class #2 (1) Enter Rockwell B scale hardness and tensile strength data appearing in Table 6 (Reference [5]) or alternatively in Wilson (Instron) Desk Chart 60 [7], for soft steel, gray and malleable cast iron and most non-ferrous metals, into Excel (or equivalent) and plot tensile strength as a function of Rockwell hardness andIn the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Hardness conversion tables for Rockwell, Brinell, Vickers. Welcome visitor you can login or create an account . Home Wish List (0) My Account Shopping Cart Checkout ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.AISI 304 Stainless Steel (UNS S30400, SS 304) AISI 304 stainless steel (UNS S30400) is the most widely used stainless steel, containing 18-20% Cr and 8-10.5% Ni, and also known as 18-8 stainless steel.SS 304 is non-magnetic under annealing conditions, but after cold working (such as stamping, stretching, bending, rolling), part of the austenite structure may be converted into . Rockwell and Brinell hardness are two of the most common tests used to measure the hardness of iron castings The hardness test is done to determine if the hardness and tensile strength still need to be improved with a machining process, especially in producing rough metal castings. The tests are.

Ultimate tensile strength of Inconel 718 depends on heat treatment process, but it is about 1200 MPa. . and water generally increases with hardness. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness . Vickers and Rockwell). There are tables that are available correlating the hardness numbers . Rockwell: Vickers: Brinell: Tensile strength: HRC: HRA: HV: HB: . ③ Rebound hardness. Rebound hardness testing is primarily used for metal materials. The method involves using a special small hammer that is dropped from a .

disadvantages of rockwell hardness test

Shear strength Yield point θ 12 Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F HB − − = π 2 1.854 D F HV =SS410 has good tensile strength, creep and fatigue strength and other mechanical properties, mainly used in steam turbines, jet engines and gas turbines. . elongation, reduction in area, Brinell and Rockwell hardness, .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes.Conversion of hardness-to-hardness or hardness-to-tensile-strength values for unalloyed and low-alloy steels and cast iron. Try out our online tool now! . Brinell hardness: HB: 76 - 618: Rockwell hardness: HRB: 41 - 105: Rockwell hardness: HRF: 82.6 - 115.1: Rockwell hardness: HRC: . Test in one of our 14 certified testing laboratories .

Ultimate tensile strength is often shortened to “tensile strength” or even to “the ultimate.” . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load .

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The ultimate tensile strength and 0.2% yield strength of this steel correlated well with hot microhardness data at test temperatures up to 400°C using Cahoon's expressions sigmauts = (H/2.9)(n/0. . Performing hardness testing can take many forms, depending on the protocols followed. There are many hardness scales and one of the most common is the Rockwell scale. To convert Rockwell Hardness to Tensile Strength, use a polynomial equation developed by modeling the tested materials. The general formula is: TS = c3 * RH^3 + c2 * RH^2 + c1 .Brinell hardness test is one of indentation hardness tests, . The ultimate tensile strength is the maximum on the engineering stress-strain curve. . Common indentation hardness scales are Brinell, Rockwell and Vickers. Rebound hardness. Rebound hardness, also known as dynamic hardness, measures the height of the “bounce” of a diamond .

Testing coarse material with the Brinell hardness testing method. The Brinell hardness tester uses the oldest method of hardness testing commonly used today. It was invented in Sweden by Dr. Johan August Brinell in 1900. This test is often used to determine the hardness of castings and forgings whose grain structure is too coarse for accurate Rockwell or Vickers testing.Rockwell hardness tester for load range of 10 to 150 kg & 3 to 45 kg with touch screen. . Carbon testing; Vickers (HVT) Brinell (HBT) Test load. 1 . 250 kg; Standards. ISO 6508; ISO 2039; ASTM E18; . S-N test DIN 50100; ILSS; Tensile Strength; Yield Point; News & Events. testXpo; Digital Events; ZwickRoell Academy; Case Studies;

Test Scales Rockwell and Rockwell Superficial Rockwell Rockwell and Rockwell Superficial Standard JIS B 7726 ISO 6508-2 ASTM E18-10 Preliminary Test Force 98.07N (10kgf), 29.42 (3kgf) 98.07N (10kgf) 98.07N (10kgf), 29.42 (3kgf) CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. . Tensile Strength (MPa) Steel & Cast Steel: 83-976: 140-651: 19.8-68.5: 59.6-99.6: 60.2-88.5: 26.4-99.5: . Reviews about CMX1000 Portable Hardness Tester Rockwell Brinell Vickers .

Active servers. Smogon University (21448) play.pokemonshowdown.com. China (164) china.psim.us. freedomsk,ublt1,fskse,starmind,zerodragon123. Smogon Tournaments (46) smogtours.psim.us. chaos.

rockwell hardness tester brinell tensile strength|rockwell vs brinell hardness test